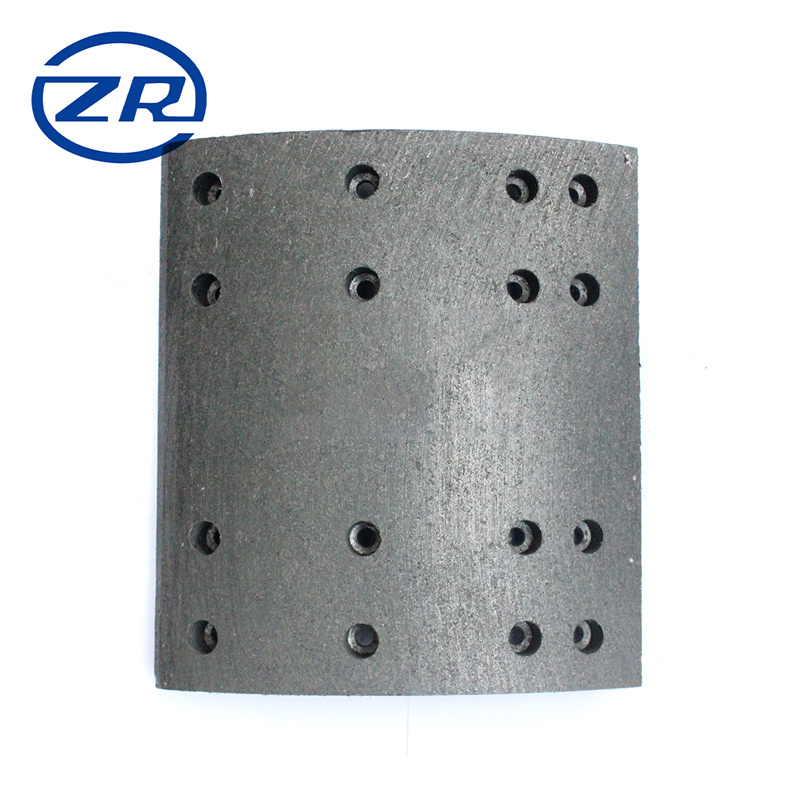

Beral Brake Lining 4515 Qianjiang Friction Material

Product Description

Brake lining NO.: FMSI 4515

Size: 206*177.8*18.5/15.7 210*177.8*18/11.4

Application: FAW TRUCK

Material: Non-asbestos, synthetic fibre,Semi-Metal

Specifications

1. Noiseless, 100% asbestos free and excellent finishing.

2. Longlife time in toghest road condition.

3. Exceptional stopping power.

4. Lower dust level.

5. Works quietly.

Advantages

1. Suitable and stable friction coefficient

The coefficient of friction is one of the most important performance indicators for evaluating any kind of friction material, and it is related to the performance of the transmission and braking functions of the friction plate. Our company adds high-temperature friction modifier fillers to the friction materials to reduce and overcome “thermal recession” and ensure that the product has a stable friction coefficient.

2. Good wear resistance

The wear resistance of a friction material is a reflection of its service life, and it is also an important technical and economic index to measure the durability of a friction material. The better the wear resistance, the longer its service life. Our company chooses suitable materials, which can effectively reduce the working wear of materials, especially thermal wear, and prolong their service life.

3. has good mechanical strength and physical properties

Before assembly and use of friction material products, mechanical processing such as drilling, riveting and assembly is required to make brake pad assemblies or clutch assemblies. In the process of friction work, the friction material not only has to withstand high temperature, but also bears relatively large pressure and shear force. Therefore, it is required that the friction material must have sufficient mechanical strength to ensure that no damage or fragmentation occurs during processing or use. The clutch plate is required to have sufficient impact strength, static bending strength, maximum strain value and rotational damage strength. The fiber reinforced material used by our company is used as the base material, which endows the friction product with sufficient mechanical strength, so that it can bear the load force of the grinding and riveting process of the friction plate during the production process and the friction due to braking and transmission during use. Impact force, shear force, pressure generated.