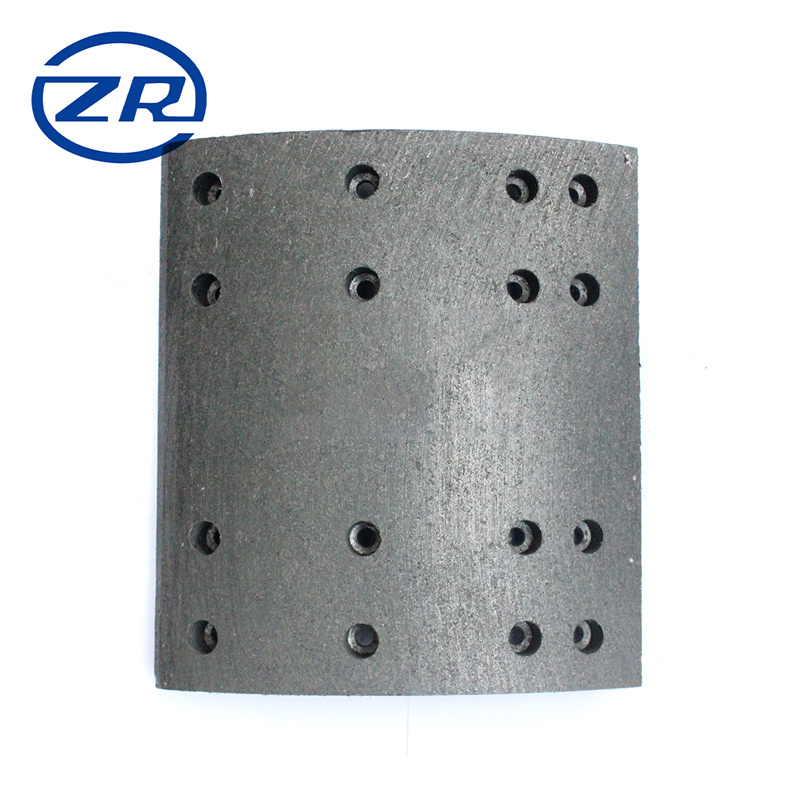

EQ153 R flexible brake lining

Product Description

Brake lining NO.: WVA 19032

Size: 220*180*17.5/11

Application: Benz Truck

Material: Non-asbestos, synthetic fibre,Semi-Metal

Specifications

1. Noiseless, 100% asbestos free and excellent finishing.

2. Longlife time in toghest road condition.

3. Exceptional stopping power.

4. Lower dust level.

5. Works quietly.

The material requirements of the brake friction plate have these four aspects

The brake friction plate and the brake disc rub against each other to generate braking torque, so the friction plate is a part that bears relatively high pressure and is easily affected by temperature, mechanical force and chemical effects. In order to ensure the life and use effect of the friction plate, the friction plate used Stable performance and high quality are required, and material is a key factor affecting performance and quality, which puts forward certain requirements for the material of the friction plate.

1. The material does not contain asbestos

The material requirements for brake friction linings are first of all not to contain asbestos, not only that, friction materials should also try to avoid expensive and unstable fibers and sulfides. Proper friction lining formulation material will ensure proper compressive strength. Friction lining materials basically consist of four raw materials: metallic materials, filler materials, slip agents and organic materials. The relative proportions of these materials depend on the particular situation in which the friction plate is used and the required coefficient of friction. Asbestos has been proven to be an effective wear-resistant material in friction plate formulation materials, but after people knew that asbestos fibers were harmful to health, this material was gradually replaced by other fibers. Now, the brake friction plate should not contain asbestos, the asbestos-free friction plate has a high friction coefficient, good mechanical strength, and the environmental-friendly non-asbestos brake shoe has a small thermal recession.

2. High coefficient of friction

For the material of the friction plate, it is also required that its coefficient of friction should be high, and it should be stable under various working conditions. The dynamic friction coefficient of the brake lining determines the magnitude of the braking force and also plays a decisive role in the balance of the brake and the stability of the winch control during braking. A reduction in the coefficient of friction causes a considerable change in braking performance, perhaps resulting in a substantial increase in stopping distance. Therefore, the coefficient of friction of thebrake lining must be guaranteed to remain stable under all conditions (speed, temperature, humidity and pressure) and throughout their service life.

3. Low braking noise

It is required that the braking noise of the friction lining produced by the material should be low. Generally speaking, the noise is caused by the vibration caused by the unbalanced friction between the brake pad and the brake disc. The sound wave of this vibration can be identified in the car. There are also many kinds of noise during the braking process. We generally distinguish them according to the stage of the noise, such as the noise generated at the moment of braking, the noise accompanying the entire braking process, and the noise generated when the brake is released. The low-frequency noise of 0-50Hz is imperceptible in the car, and the driver will not consider the noise of 500-1500Hz as braking noise, but the driver of high-frequency noise of 1500-15000Hz will consider it as braking noise. The main determinants of brake noise include brake pressure, pad temperature, vehicle speed and climatic conditions. In order to prevent noise, a vibration-absorbing device is usually used on the brake friction plate, including a vibration-absorbing plate and an anti-vibration glue.

4. Strong shear strength

The shear strength is to ensure that the friction lining will not fall off or crack even under harsh conditions, and the shear strength is a standard to measure the performance of the friction lining, so the shear strength of the friction lining material is required to be strong. Whether it is the shear strength of the friction pad itself or the bond between the brake pad and the back plate, it must be ensured that it will not fall off or crack even under extreme conditions.