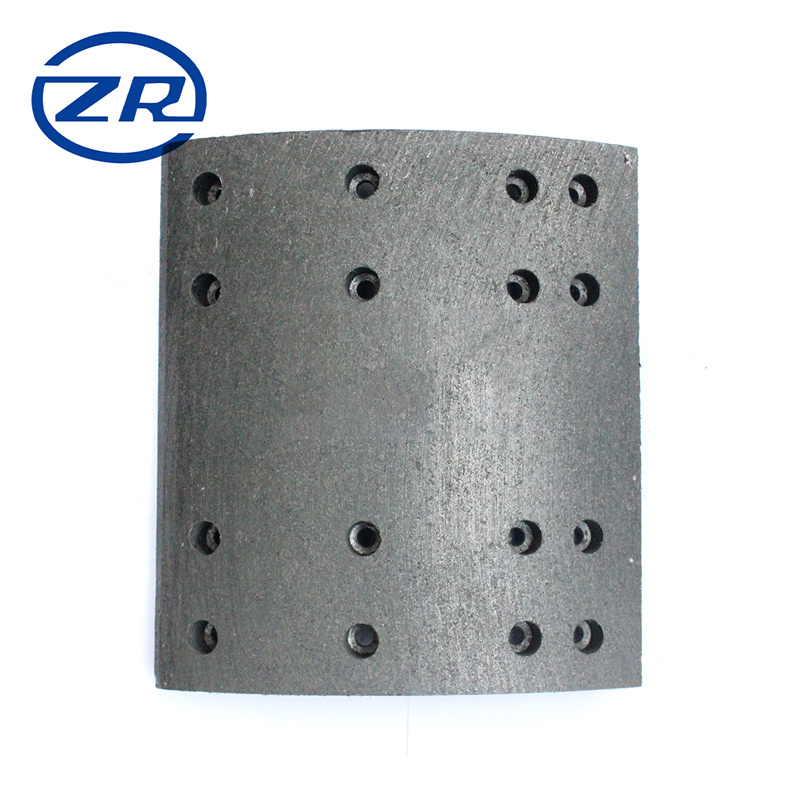

19032 Synthetic Fibre Of Brake Lining

Product Description

Brake lining NO.: WVA 19032

Size: 220*180*17.5/11

Application: Benz Truck

Material: Non-asbestos, synthetic fibre,Semi-Metal

Specifications

1. Noiseless, 100% asbestos free and excellent finishing.

2. Longlife time in toghest road condition.

3. Exceptional stopping power.

4. Lower dust level.

5. Works quietly.

Material Of Non-asbestos Friction Material

1. Semi-metallic friction material

Disc brake pads for cars and heavy vehicles. The composition of its material formula usually contains about 30% to 50% iron metal objects (such as steel fiber, reduced iron powder, foam iron powder). The semi-metallic friction material is thus named. It is an asbestos-free material developed to replace asbestos. Its characteristics: good heat resistance, high absorbed power per unit area, large thermal conductivity, and can be applied to the braking conditions of automobiles running at high speeds and heavy loads. However, it has disadvantages such as high braking noise and brittle corners.

2.NAO friction material

In a broad sense, it refers to non-asbestos-non-steel fiber type friction materials, but the disc disc also contains a small amount of steel fibers. In most cases, the base material in NAO friction materials is a mixture of two or more fibers (inorganic fibers and a small amount of organic fibers). Therefore, NAO friction material is a non-asbestos mixed fiber friction material. Usually the brake pads are chopped fiber friction pads, and the clutch pads are continuous fiber friction pads.

3. Powder metallurgy friction material

Also known as sintered friction material, it is made by mixing iron-based and copper-based powder materials, pressing, and sintering at high temperature. It is suitable for braking and transmission working conditions at relatively high temperature. Such as: braking and transmission of heavy construction machinery and trucks. Advantages: long service life; Disadvantages: high product price, large braking noise, heavy and brittle, and large dual wear.

4. Carbon fiber friction material

It is a kind of friction material made of carbon fiber as reinforced material. Carbon fiber has the characteristics of high modulus, good thermal conductivity, and heat resistance. Carbon fiber friction material is one of the best performance among various types of friction materials. Carbon fiber friction plate has high absorption power per unit area and light specific gravity, which is especially suitable for the production of aircraft brake pads. However, because of its high price, its application range is limited and its output is small. In the carbon fiber friction material component, in addition to carbon fiber, graphite, a compound of carbon, is also used. The organic binder in the components is also carbonized, so carbon fiber friction materials are also called carbon-carbon friction materials or carbon-based friction materials.