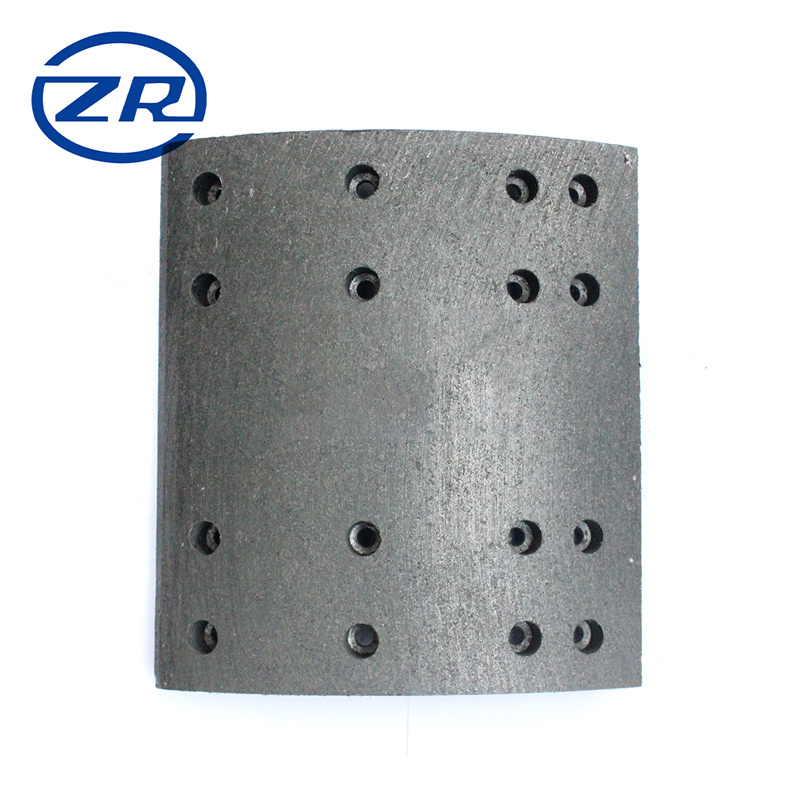

Universal Truck Parts 10HOWO Seiko Brake Lining

Product Description

Brake lining NO.: 10HOWO

Size: 210 *220*14.5

Application: HOWO TRUCK

Material: Non-asbestos, synthetic fibre,Semi-Metal

Specifications

1. Noiseless, 100% asbestos free and excellent finishing.

2. Longlife time in toghest road condition.

3. Exceptional stopping power.

4. Lower dust level.

5. Works quietly.

How to choose Brake Lining

During the use of the brake pads, due to friction, the friction blocks will be gradually worn out. After the friction material is used up, the brake pads should be replaced in time, otherwise the steel plate will directly contact the brake disc, and eventually the braking effect will be lost and damaged. Brake discs affect driving safety. For your driving safety, please check and replace the brake pads regularly.

Automotive friction materials are the key materials for friction (contact) brakes and clutches for braking and transmission. Automobile brake pads are the key components of vehicle braking transmission, which directly affect the driving safety performance of automobiles. The main issues of automobile brakes in the 21st century are safer, lighter and more environmentally friendly. This requires not only the development of new materials, but also the use of new structures and new systems in order to greatly improve the overall performance of the brakes and achieve light weight. . Its performance directly affects the normal use of the car braking system, which is related to the realization of car comfort, safety and other performances.

The production process of automobile friction materials can be roughly divided into three categories according to the processing temperature: hot pressing process, cold pressing process and warm pressing process. The hot pressing process has a long history of application, mature technology, and wide application range. At present, it is applied by most friction material manufacturers at home and abroad. Both the cold pressing and warm pressing processes belong to the low-temperature forming process, which is a new type of friction material production process, with superior performance. Although the research on these new processes has achieved certain results, they are still in the exploratory stage, and the technology is still immature and needs to be further developed.