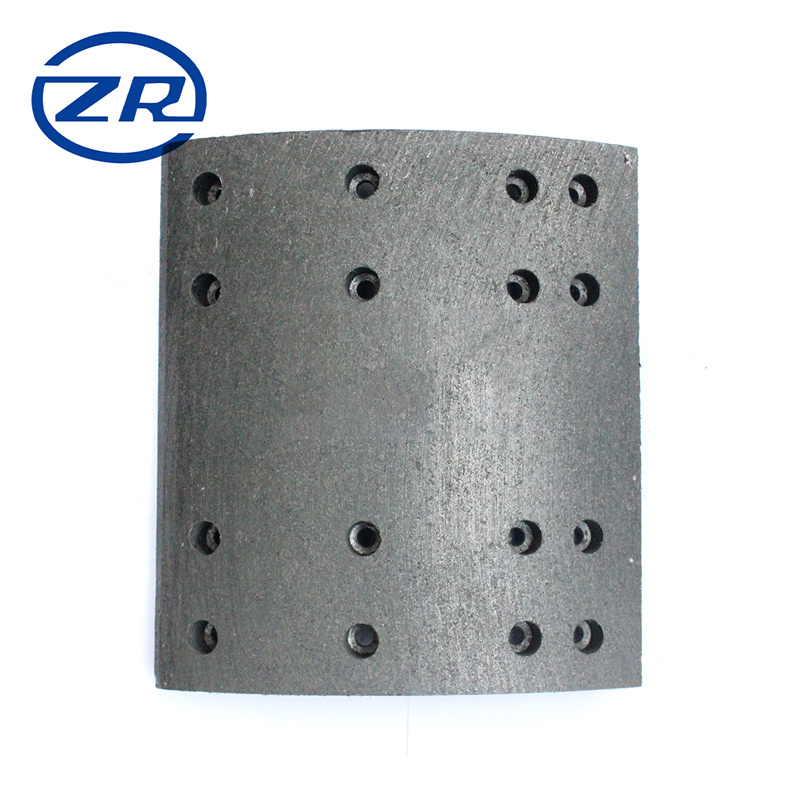

Lining Brake Persona 29938 Brand Qianjiang Friction

Product Description

Brake lining NO.: WVA 19032

Size: 220*180*17.5/11

Application: Benz Truck

Material: Non-asbestos, synthetic fibre,Semi-Metal

Specifications

1. Noiseless, 100% asbestos free and excellent finishing.

2. Longlife time in toghest road condition.

3. Exceptional stopping power.

4. Lower dust level.

5. Works quietly.

Riveting Brake Linings

The brake lining refers to the brake pad, that is, there is a very thin lining on the side of the brake pad. The brake pad is what we commonly call the brake pad, and there is a warranty time for maintenance. The brake lining is specially used for the rear drum brake. The friction material on the rear drum brake is lined separately, and the professional term is riveted. In fact, it is the lining of the brake pads. Usually the verbal brake pad is actually a brake pad assembly composed of a lining and a friction pad through riveting.

Brake Shoe Linings

Most cars adopt the structure of front disc and rear drum brakes. Generally, the front brake shoes wear out relatively quickly, and the rear brake shoes are used for a relatively long time. During daily inspection and maintenance, the following points should be paid attention to aspect:

1. Under normal driving conditions, check the brake shoe every 5,000 kilometers, not only to check the remaining thickness, but also to check the wear state of the shoe, whether the degree of wear on both sides is the same, whether it can return freely, etc., and find that it is abnormal The situation must be dealt with immediately.

2. Brake shoes are generally composed of iron liner and friction material. Do not wait for the friction material to wear out before replacing the shoe. For example, for the front brake pads of the Jetta, the thickness of the new pads is 14 mm, while the limit thickness for replacement is 7 mm, including the thickness of the iron liner of more than 3 mm and the thickness of the friction material of nearly 4 mm. Some vehicles have a brake shoe alarm function. Once the wear limit is reached, the instrument will alarm and prompt to replace the brake shoe. The shoes that have reached the limit of use must be replaced, even if they can still be used for a period of time, the effect of braking will be reduced and the safety of driving will be affected.

3. When replacing, the brake pads provided by the original spare parts should be replaced. Only in this way can the braking effect between the brake pads and the brake disc be the best and the wear and tear should be minimized.

4. Special tools must be used to push back the brake cylinder when replacing the shoes. Do not use other crowbars to press back hard, which will easily lead to the bending of the guide screw of the brake caliper and cause the brake pad to be stuck.

5. After replacing the shoe, be sure to step on the brake several times to eliminate the gap between the shoe and the brake disc, resulting in no brake on the first foot, which is prone to accidents.

6. After the brake shoe is replaced, it needs to run in for 200 kilometers to achieve the best braking effect. The newly replaced shoe must be driven carefully.